- 1

Next, due to that strength, the Apollo 10 can be equipped with the most powerful standard spindle in the industry, a 28.8 HP from Saccardo ensuring that you can cut through the hardest materials with ease.

The Apollo Series of 5 axis CNC saws from Nova Stone Machinery began with a unique approach. Rather than manufacturing machines that are copies of existing competitors, our factory began with a clean slate and a clear objective: To make the most productive, precise and longest lasting machines in the world.

How are our saws different?

The Apollo Series of 5 axis CNC saws from Nova Stone Machinery began with a unique approach. Rather than manufacturing machines that are copies of existing competitors, our factory began with a clean slate and a clear objective: To make the most productive, precise and longest lasting machines in the world.

How are our saws different?

At Nova Stone Machinery, every detail is engineered with precision.

Nova Stone Machinery delivers powerful, precise, and durable CNC solutions.

First, our factory is a leader in aerospace. This matters because in the aviation and space industries, there is no margin for error. Our frames are made in-house, using one of the world's largest CNC machines.

Speaking of frames, our saws weigh as much as double of competitors' machines. Does that matter? Yes, as this provides rigidity, and allows the frame to absorb vibration, rather than having those vibrations transmitted to the saw's components.

Tolerances are measured in microns, instead of fractions of an inch.

Facilisi mattis phasellus tortor. Egestas suspendisse tristique quam viverra natoque ac morbi

Tortor congue velit cidunt pellentesque blandit fringilla aliquam pretium lobortis lacus

Consequat, sed sem sit sit dui vestibulum aliquam pharetra mi velit in nibh orci blandit in et

With decades of expertise in aerospace and industrial engineering, our factory brings cutting-edge technology to the stone industry. Our Apollo Series is designed from the ground up to deliver accuracy, speed, and strength beyond any competitor.

Next, due to that strength, the Apollo 10 can be equipped with the most powerful standard spindle in the industry, a 28.8 HP from Saccardo ensuring that you can cut through the hardest materials with ease.

21 inch touchscreen monitor. Standard.

LED Lighting

Clearly see what your are working on.

Hydraulic tilt table.

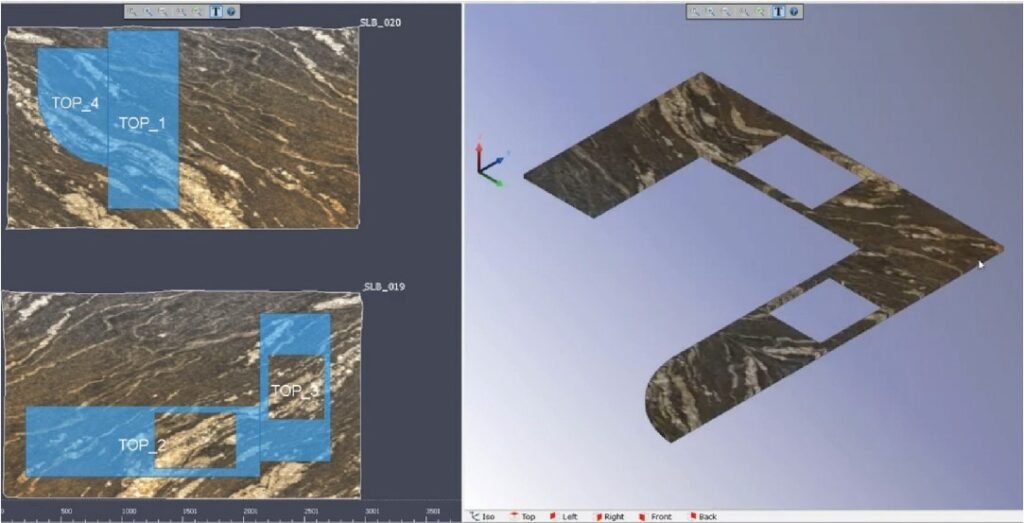

When the slab is placed on the table, the user can capture live view images that are transmitted to the Photo Digitizer software. The software analyzes these images and automatically detects any non-conformities such as cracks, deformations, or other defects present in the slab. Based on this surface data, along with the workpiece’s size and thickness, the system generates the optimal layout for the CAD application to process the workpiece. Using the Photo Digitizer module within the CNC software, the photograph can also be corrected or manipulated as required.

When the slab is placed on the table, the user can capture live view images that are transmitted to the Photo Digitizer software. The software analyzes these images and automatically detects any non-conformities such as cracks, deformations, or other defects present in the slab. Based on this surface data, along with the workpiece’s size and thickness, the system generates the optimal layout for the CAD application to process the workpiece. Using the Photo Digitizer module within the CNC software, the photograph can also be corrected or manipulated as required.

With the powerful Rocket side spindle, you’ll cut out sinks in a fraction of the time.

With the Apollo 15’s tool changer, accelerate your production even further!

It’s simple. If you miter, you need a touch probe. For perfect miters, time after time.

As you know, slabs vary in thickness, which is an issue when mitering. Probe presetting devices measure blade diameter.

TABLE SIZE: 149″ x 94.5″

FOOTPRINT: 240″ x 163″

AXIS STROKE: X axis: 149″

Y axis: 94.5″ Z axis 14.9″

TABLE SIZE: 137″ x 79″

FOOTPRINT: 222″ x 150″

AXIS STROKE: X axis: 137″

Y axis: 79″ Z axis 14″